Environmental Sustainability|Greenhouse Gas Emission

Nuvoton actively reduce the environmental impact of our business operations by investing in innovative technologies and initiating layouts for renewable energy and net carbon zero emissions. We enhance resource use efficiency and implement waste management to respond to the continuously evolving international environmental regulations, extreme climate events, and other risks. By estimating financial impacts and planning management costs in advance, we formulate environmental strategies and build operational resilience for the company.

48.8

%

Approved SBTi Near-Term Target: Commitment to Reduce Scope 1 and 2 Emissions by 2030 Compared to the 2022 Baseline

25

%

Approved SBTi Near-Term Target: Commitment to Reduce Scope 3 Emissions by 2030 Compared to the 2023 Baseline

1163000

kWh

Nuvoton Taiwan's Annual Electricity Saving Achievement in 2024

Greenhouse Gas Management

Nuvoton has established a greenhouse gas (GHG) inventory mechanism in accordance with ISO 14064-1 standards and the guidelines of Taiwan's Environmental Protection Administration (EPA). Since 2009, NTC Taiwan has regularly conducted Scope 1 and Scope 2 GHG inventories based on ISO 14064-1 and obtained third-party verification. Starting in 2023, NTC Japan adopted the same inventory and verification practices to ensure data credibility and reporting quality.

2024 Scope 1 and Scope 2 Emissions1

In 2024, Nuvoton's total Scope 1+2 GHG emissions amounted to 125,439 tCO₂e, representing a reduction of 22,403 tCO₂e (16%) compared to 2023. Of this, direct emissions (Scope 1) from NTC Taiwan and NTC Japan totaled 56,228 tCO₂e, while indirect emissions (Scope 2) reached 67,385 tCO₂e. Subsidiaries contributed an additional 1,826 tCO₂e in Scope 1 + 2 emissions.

1 All GHG data disclosed in this section are aligned with SBT target setting and calculated using GWP from IPCC AR6 (2021).

Scope 1 and Scope 2 Emissions for Nuvoton Taiwan & Japan (Past Three Years) and 2030 Target (tCO₂e)2

2 Note: GHG data are aligned with SBT target setting and calculated using GWP values from IPCC AR6 (2021).

2024 Scope 3 Emissions (tCO₂e)3

In 2024, Nuvoton's Scope 3 GHG emissions totaled 8,164,676 tCO₂e, a reduction of 243,925 tCO₂e compared to 2023. The primary sources of Scope 3 emissions were Category 1 (Purchased Goods and Services, 5%) and Category 11 (Use of Sold Products, 93%), which together accounted for 98% of total Scope 3 emissions.

Scope 3 Emissions by Category (Past Two Years)4

3 Note: Categories 10–12 in Scope 3 were added to support SBT target setting and have not yet undergone third-party verification. Verification is scheduled to begin in 2026. All other applicable categories have been verified by third parties.

4 Scope 3 emissions have been inventoried across all applicable categories under the GHG Protocol since 2023. For data prior to 2022, please refer to historical sustainability reports.

GHG Reduction Measures

Nuvoton employs diverse and targeted strategies across different scopes to reduce carbon emissions:

- Scope 1: In Nuvoton Taiwan, over 90% of Scope 1 emissions are attributable to fluorinated GHGs (PFCs). The company has progressively implemented fluorinated gas treatment systems, achieving an 88% reduction rate by 2025. In Nuvoton Japan, the focus is on phasing out the gas-fired cogeneration system (CGS) system and replacing steam-powered absorption chillers with high-efficiency electric chillers to effectively reduce direct emissions.

- Scope 2: Scope 2 emissions primarily from purchased electricity. Nuvoton actively implements energy-saving and renewable energy initiatives to improve energy efficiency and reduce electricity consumption. In Nuvoton Taiwan, we have begun replacing energy-intensive equipment such as pumps, chillers, and high-vacuum generators, installed solar panels, introduced AI-controlled chiller systems, and launched a program to replace electric boilers with gas boilers. In Japan, Nuvoton has adopted high-efficiency heat exchangers for gas-fired cogeneration system (CGS) system, installed LED lighting, and procured energy-saving equipment including pumps, chillers, and air handling units. Nuvoton Japan also actively purchases offsite renewable electricity and obtains non-fossil fuel certificates.

Scope 3: Nuvoton is committed to driving decarbonization across its supply chain through carbon management, partnerships for low-carbon transformation, adoption of third-party certifications, and green product innovation. The electricity consumption during the use phase of sold products (Category 11) is the largest contributor to Scope 3 emissions of Nuvoton. To address this, the company continues to develop green products by adopting advanced process technologies below 55nm and innovative packaging solutions to enhance chip performance and reduce energy consumption.

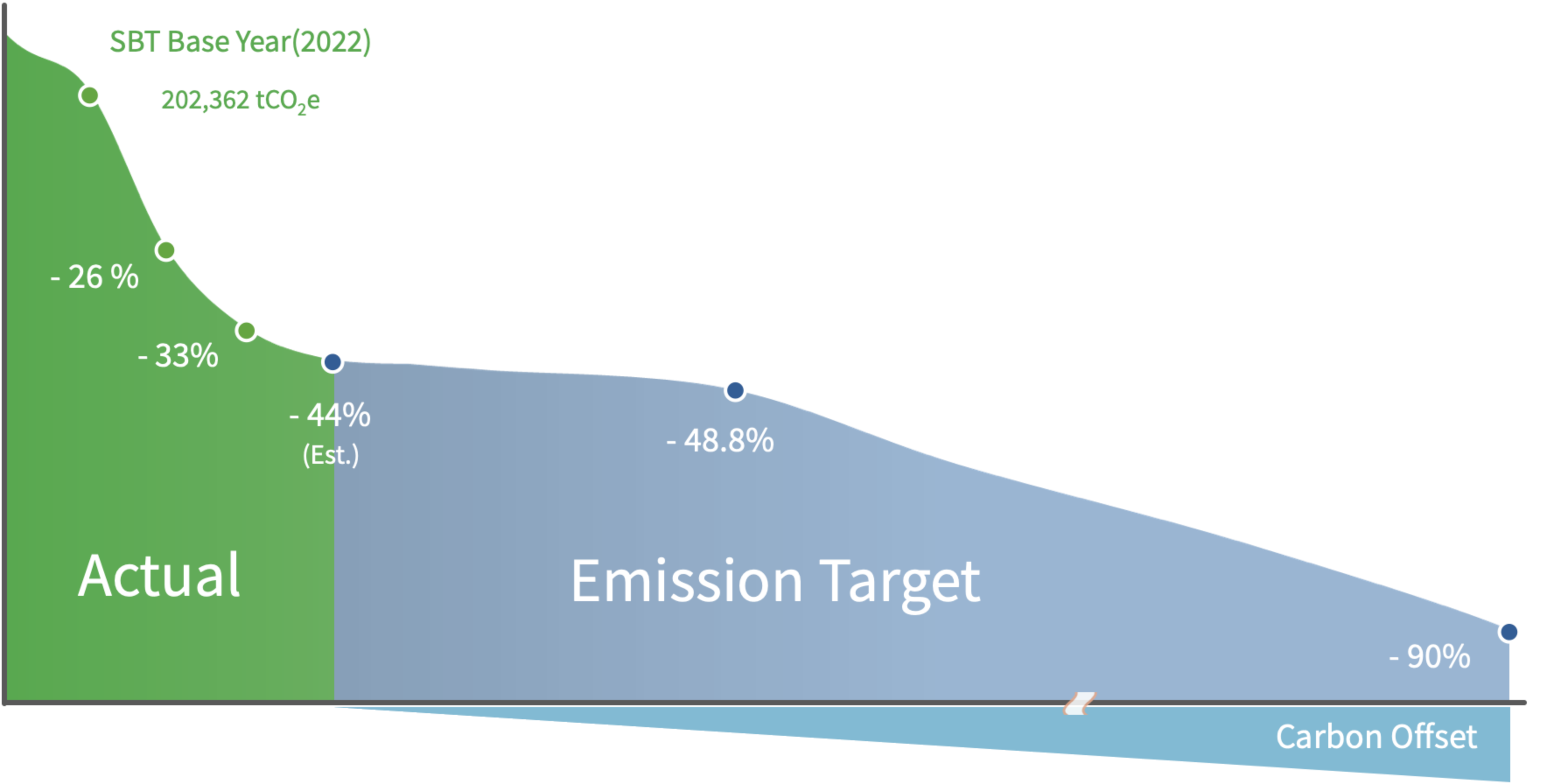

Reduction Target Setting Nuvoton follows the Science Based Targets initiative (SBTi) standards, committing to net-zero carbon emissions by 2050. The company submitted its 2030 targets to SBTi in October 2024 and received short-term target approval on March 28, 2025.

Carbon Reduction Targets and Net-Zero Commitment

By 2030

Scope 1 & Scope 2: Reduce emissions by 48.8% compared to the 2022 baseline year (SBTi-approved).

By 2030

Scope 3: Reduce emissions by 25% compared to the 2023 baseline year (SBTi-approved).

By 2050

Achieve net carbon zero as a 2050 long-term commitment.

Nuvoton (Global) Net Carbon Zero Pathway

Nuvoton Taiwan's Greenhouse Gas Reduction Project

| Scope | Category | Initiative | Energy Red. Target (k kWh/yr) | GHG Red. Target (tCO2e/yr) | Actual GHG Red. (tCO2e/yr) | Comp. | Description |

|---|---|---|---|---|---|---|---|

| 1 | Reduction | Scrubbers installation | - | 10,521 | 11,165 | 100% | Scope 1: -17%/year |

| 2 | Energy-saving Equipment | High-Efficiency Equipment (pump, chiller, LED, HVAC, etc.) | 620 | 306 | 199 | 100% | Replacement of outdated equipment in various facilities |

| Energy-saving Equipment | Chiller #4 upgrade and replacement | 520 | 256 | 0 | 80% | Expected completion Q1 2025 | |

| Process Optimization | Chiller System (AI Control) | 200 | 99 | 99 | 100% | AI software completed, online in Dec. | |

| Alternative Energy | Replacement of Electric Boilers with NG Boilers | 150 | 74 | 109 | 100% | Online in Dec. (-220 kWh/year) | |

| Total | 1,490 | 11,256 | 11,572 | 103% | |||

Nuvoton Japan's Greenhouse Gas Reduction Project

| Scope | Category | Initiative | Energy Red. Target (k kWh/yr) | GHG Red. Target (tCO2e/yr) | Actual GHG Red. (tCO2e/yr) | Comp. | Description |

|---|---|---|---|---|---|---|---|

| 1 | Cogeneration | high-efficiency heat exchangers | - | 2,982 | 3,000 | 100% | Equipment Upgrade at Nagaokakyo Cogeneration Plant |

| 2 | Energy-saving Equipment | Replacement to LED | 1,020 | 448 | 509 | 100% | |

| Energy-saving Equipment | High-Efficiency Equipment (pump, chiller, AHU etc.) | 410 | 196 | 196 | 100% | 53 improvements | |

| Renewable Energy | Off-site PPA | - | 3,657 | 0 | 0 | Arai Plant scheduled for implementation in 2025 | |

| Alternative Energy | Purchase of non-fossil fuel certificates | - | 2,225 | 2,225 | 100% | Done | |

| Total | 1,430 | 9,508 | 5,930 | 62% | |||